This is an old revision of the document!

Table of Contents

Report

Autonomous Environmental Buoy/Regatta Beacon

Authors:

Bennet Möller

Emil Konrad Wlazlo

Mateusz Tarkowski

Toon Van den Bleeken

Acknowledgement

We would like to take this opportunity to thank all people and institutions involved in this project. We are very grateful for giving us the opportunity to work and study at “Instituto Superior de Engenharia do Porto”and at “Laboratorio de Sistemas Autonomos”. Special thanks should be offered to Mrs. Benedita Malheiro, Mr. Paulo Ferreira , Mr. Manuel Silva, Mrs. Nídia Sá Caetano, Mr. Pedro Barbosa Guedes, Mrs. Christina Ribeiro and Mr. António Ferreira da Silva, who have greatly assisted us throughout the course of the

project. We would like to express our gratitude for holding the weekly meetings, coming into contact with third parties, and even driving us around.

In this place, we would especially like to bring up the name of Mrs.

Benedita Malheiro. Without your involvement and sincere interest in the project, it would be hard for us to achieve as much as we have.

We are also immensely thankful to Mr. Fernando Ferreira and Mr. Mario Alvim. Only with your help were we able to make progress with the steel structure and fibreglass hull.

Simultaneously we are indebted to Mr. Eduardo Alexandre Pereira da Silva, Mr. João Paulo Baptista, and Mr. José Almeida for allowing us to work at LSA, providing us with components, and supporting us regarding our programming part.

Last but not least, we would like to thank all our teachers: Mrs. Ana Barata, Mr. Luis Cardia Lopes, Mr. Luis Castanheira, Mrs. Ana Marques, Mr. Alberto Pinto, Mrs. Andreia Taveira da Gama. Participating in such interesting courses led by such enthusiastic teachers, was an educational and pleasant experience.

Abstract

Buoys are nowadays more important than ever before. They come in a multitude of types and can perform various functions. Nevertheless, the market is not exhausted yet and it does need a breath of fresh air. For this purpose we undertook the task of constructing an original buoy with two major applications: collection of weather data and assistance in autonomous sailing boat regattas.

First we analysed the market of buoy manufacturers and their products. We focused on three of the buoys’ aspects: construction, functionality, and innovation. As far as construction is concerned, we examined the design and the layout of the buoys’ components, the type of materials buoys are made of, and the hardware they use. In terms of functionality, we researched the buoys’ possible functions and how exactly they perform them. With this background knowledge we decided roughly what our buoy should look like. We then proceeded with a more extensive research on each individual component, and finally made a list of those that we could use. Some of the major tasks of our project included designing an original stainless steel structure, preparing signal and power schematics, and programming the software.

The final product of our project is a functioning buoy. It consists of a fibreglass hull, a stainless steel structure, and various electronic components including Wi-Fi and GNSS antennas, CTD and wind sensors etc. Because of its small size and lightness, and the fact that it can perform many functions including weather data collection, storage, and sending, the buoy constitutes a favourable alternative to many other buoys. Moreover, it combines two major and significant applications, i.e. collection of weather data and assistance in regattas, which makes it the first of the type. Nevertheless, the buoy unfortunately does have two limitations. First of all, it can only hold up a total weight of around 40kg. Secondly, it cannot be used on the sea or ocean.

Glossary

Introduction

CTD – Conductivity, Temperature and Depth sensor, developed by ISEP.

EPS - European Project Semester, type of ERASMUS Student Exchange program in which we are participating.

GNSS - Global Navigation Satellite System, is a system of satellites that provide autonomous geo-spatial positioning with global coverage.

LSA - Autonomous Systems Laboratory, department of ISEP.

UV - Ultraviolet light is electromagnetic radiation with a wavelength shorter than that of visible light, but longer than X-rays, that is, in the range between 400 nm and 10 nm.

State of the Art

µC – Microcontroller.

Accelerometer - Is a device that measures acceleration.

BD - Blu-ray Disc is an optical disc storage medium designed to supersede the DVD format.

Bluetooth - Is a wireless technology standard for exchanging data over short distances from fixed and mobile devices, creating personal area networks with high levels of security.

CAN - Controller Area Network, type of communication interface.

Catenary - The curve that an idealized hanging chain or cable assumes under its own weight when supported only at its ends.

CD - The compact disc, is an optical disc used to store digital data.

CEC - Consumer Electronics Control, type of communication interface.

CPU - Central processing unit, is the hardware within a computer that carries out the instructions of a computer program by performing the basic arithmetical, logical, and input/output operations of the system.

Crown - The bottom portion of an anchor.

DVD - Is an optical disc storage format, who offer higher storage capacity than compact discs while having the same dimensions.

E-compass – Electronic compass.

FEUP - Faculdade de Engenharia da Universidade do Porto, University of Porto faculty.

Fluke - The triangular blade at the end of an arm of an anchor, designed to catch in the ground.

GPIO - General Purpose Input/Output.

GSM - Global System for Mobile Communications, communication standard.

Gyroscope - A gyroscope is a device for measuring or maintaining orientation, based on the principles of angular momentum.

Hall effect - A phenomenon that occurs when an electric current moving through a conductor is exposed to an external magnetic field applied at a right angle, in which an electric potential develops in the conductor at a right angle to both the direction of current and the magnetic field.

HDMI - High-Definition Multimedia Interface, type of communication interface.

Holding power - The value of the maximum pulling force an anchor accepts without dragging in given conditions.

I/O – Input/output.

I2C - Inter-Integrated Circuit, referred to as I-squared-C, type of communication interface.

I2S - Also known as Inter-IC Sound, Integrated Interchip Sound, type of communication interface.

IEEE - Institute of Electrical and Electronics Engineers, a professional association of engineers dedicated to advancing technological innovation and excellence. It is specialized in creating international standards about electronic, IT, communication etc. technologies.

LAN - Local Area Network, is a computer network that interconnects computers in a limited area such as a home, school, computer laboratory, or office building using network media.

LED - Light-Emitting Diode.

Li-ion - Lithium-ion.

Luminous flux - A measure of the total “amount” of visible light emitted by a source.

NiCd - Nickel-cadmium.

NiMH - Nickel–metal hydride.

PCB - A printed circuit board is used to mechanically support and electrically connect electronic components.

RAM - Random-access memory, is a form of computer data storage.

RCA - Is a type of electrical connector commonly used to carry audio and video signals. The name “RCA” derives from the Radio Corporation of America.

RF - Radio Frequency.

SD card socket - Secure Digital card socket.

Shackle - Any of several devices, such as a clevis, used to fasten or couple.

Shank - The stem of an anchor, at the top of which is the anchor ring.

Stock - the crosspiece at the top of an anchor’s shank, either fixed or removable.

SLI – Start, Light, Ignition, a term used in the automotive industry.

SPI - Serial Peripheral Interface Bus, type of communication interface.

Swivel - A link, pivot, or other fastening so designed that it permits the free turning of attached parts.

Thimble - A metal ring around which a rope splice is passed.

Transformer - Device used to transfer electric energy from one circuit to another, especially a pair of multiply wound, inductively coupled wire coils that effect such a transfer with a change in voltage, current, phase, or other electric characteristic.

UART - Universal Asynchronous Receiver/Transmitter, type of communication interface.

UHF - Ultra High Frequency, radio frequency range of electromagnetic waves between 300 MHz and 3 GHz.

Ultrasonic - Acoustic frequencies above the range audible to the human ear.

UMTS - Universal Mobile Telecommunications System, is a third generation mobile cellular system for networks based on the GSM standard.

USART - Universal Synchronous/Asynchronous Receiver/Transmitter, type of communication interface.

USB - Universal Serial Bus, is an industry standard developed that defines the cables, connectors and communications protocols used in a bus for connection, communication and power supply between computers and electronic devices.

VHF - Very High Frequency, range of radio frequency electromagnetic waves from 30 MHz to 300 MHz.

Wi-Fi - Is a technology that allows an electronic device to exchange data wirelessly (using radio waves) over a computer network.

WLAN - Wireless Local Area Network.

Marketing Plan

B-to-B - Business to Business.

R&D -Research and Development.

ROI - Return on investment is used to evaluate the efficiency of an investment or to compare the efficiency of a number of different investments.

SWOT - Strengths, Weaknesses, Opportunities and Threats.

WoM - Word of Mouth, is the passing of information from person to person by oral communication.

WRSC - World Robotic Sailing Championship.

Energy and Sustainability

EPA - Environmental Protection Agency.

ISO - Is the International Organization for Standardization; it is an international standard-setting body composed of representatives from various national standards organizations.

LCA - Life Cycle Assessment.

WBCSD - The World Business Council for Sustainable Development.

WOC - World Ocean Council.

Ethics and Deontology

Code of ethics - Set of rules and principles concerning ethical way of behaving.

Deontology - Part of ethics concerning duties and obligations of human beings.

Project Development

EPDM - Ethylene propylene diene monomer.

Equilibrium position - Is a condition in which all acting influences are cancelled by others, resulting in a stable, balanced, or unchanging system.

Fibreglass - Is a fibre reinforced polymer made of a plastic matrix reinforced by fine fibres of glass.

GND - In electrical engineering, ground or earth can refer to the reference point in an electrical circuit from which other voltages are measured, or a common return path for electric current, or a direct physical connection to the Earth.

Hull - A hull is the watertight body of a floating vessel.

MAX232 - Is and integrated circuit that converts signals from an RS-232 serial port to signals suitable for use in digital logic circuits, TTL, and the other way around.

MCU - MicroController Unit.

Net force - Is the overall force acting on an object.

Potentiometer – device to regulate the voltage supply.

TTL - Transistor–transistor logic, is a widespread integrated circuit family.

Voltage regulator - Is designed to automatically maintain a constant voltage level.

1. Introduction

1.1 Group presentation

In the middle of February 2013 we started with a programme called the European Project Semester. Out of a total of 13 people that took part in it at the Instituto Superior de Engenharia do Porto, there were three teams created. Our team consisted of four members and was called Team 3 (Table 1-1). Within the scope of this programme, we were working on a major project that lasted the whole semester and were attending classes that complemented it.

Table 1-1 Team members

1.2 Motivation

There were two major concerns we had in mind when selecting the topic of our project. The first was the will of working on something interesting, and perhaps even entertaining. The second was the uncertainty of the feasibility of a given topic. After some time of brainstorming, our final choice was the “Autonomous Environmental Buoy/Regatta Beacon”. The reasons for this were threefold. First of all, it stood out among all other topics; it seemed especially interesting. Secondly, Bennet is a surfer and in general a water sports fan, therefore it was related to his interests. Moreover, none of us knew at that time much about buoys, let alone an electronic buoy, and we wanted to challenge ourselves and learn something new and perhaps useful in our future.

1.3 General Information

A buoy is a device that is used in water in such a way that it floats being partially submerged, as exemplified in Figure 1 1. It can be found at places where there is a lot of water, such as the open ocean, a river, a bay, a lake. There are many different types of buoys serving a wide range of functions, for example: warning navigators about dangers, collecting data for weather agencies, providing ships with the means of mooring. Depending on these functions, a buoy can have a size ranging from as small as a football to as big as a phone booth. The smallest buoys often do not contain any electronic equipment; they consist of an empty hull and are used, for instance, to mark the location of an anchor. The bigger buoys are mostly equipped with a multitude of electronics such as sensors, solar panels and batteries.

Figure 1-1 Example of a buoy

1.4 Project description

The task of our project was to design and construct an electronic buoy. The buoy was intended to be relatively small compared to some of the biggest existing ones, but rather complex as it was to have a number of electronic devices that would allow it to perform two different functions (these are detailed in section 1.5 below). Part of our project had been previously completed at the point when we started it, i.e. there was already an existing hull (Figure 1 2). It is a light fibreglass structure that resembles planet Saturn. It is empty inside and it possible to access the interior by unscrewing six bolts and taking off the cover.

Figure 1-2 Existing hull

1.5 Objectives

The general objective of the buoy was to measure, store and send data from its location in a river. It was intended to have two major applications:

1. assistance in autonomous sailing boat regattas

In this function the buoy was supposed to perform two tasks:

- inform the sailing boats about its location so that they travel in the right direction

- provide judges with the necessary weather data to assess each boat’s performance

2. collecting environmental data

The buoy was supposed to make measurements of selected weather conditions at a chosen site and period. Nevertheless, its future application was to be limited to Douro river and for a seven-day period.

1.6 Requirements

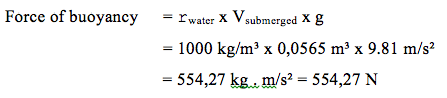

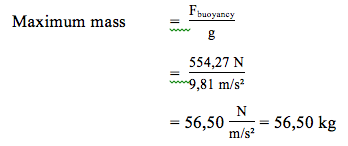

There is a number of requirements that needed to be fulfilled in order for the buoy to be operational. One of the most important was the necessity of having a specific structure attached to the hull. First of all, because of the constant exposure to sun and saltwater, it had to be made of a material resistant to corrosion and UV radiation. Secondly, it should provide the space for the attachment of some of the equipment. Furthermore, it was highly important that it was able to carry all possible loads that it would be subject to (weight of the electronic equipment, wind, rain, waves, etc.). Moreover, it was necessary that it did not exceed a certain weight to make sure it did not cause the hull to sink. In addition, it was significant that the structure had the right shape so that the centre of gravity was exactly in the centre as seen from above, and so that it was possible to take off the hull’s cover. The second requirement referred to the buoy’s electronic equipment. In the first place, it had to be waterproof. For this purpose, most of it should be placed in a special tightly sealed box and located within the fibreglass hull. All connections and plugs that came out of the box should be waterproof as well. Furthermore, all the electronic equipment had to have a defined power consumption so that it was possible to select the right type of battery. Moreover, it should have a known voltage supply in order to provide the required amount of power. In addition, it was important to know the weight and dimensions of every electronic component. This helped to determine the size of the box and to calculate the buoyancy of the buoy. It was also important to know the types of connections the sensors should have. A helpful general requirement was to assess, as far as possible, such aspects of the equipment as economy, reliability, maintenance, and ability to be reconfigured. For example, the structure that clasps the hull had to be designed, considering the possibility of attaching solar panels if they proved to be required in the future.

2. State of the Art

2.1 Introduction

The market for measuring buoys is already accessed. A general distinction can be made between measuring buoys and signal buoys. For choosing the right components and getting as much information about existing buoys, and their components as possible, we decided to analyse some of the existing buoys as well as the specific components a buoy should have. After our analyse we can conclude that, both commercial produced buoys and uniquely developed prototypes (e.g. in university research) are already on the market.

In order to find the best solution that will distinguish our proposal from the existing ones, specific environmental conditions and a buoy’s functional requirements have to be considered in our decision process. The following list shows the most important features a buoy needs to fulfil:

- UV resistant

- Saltwater resistant

- Waterproof hull

- Quick release system

- Stainless steel (for outer construction)

- Seagull protection

In this chapter we will present a summary of technical specifications regarding some of the already existing buoys, the main competitors in this field. Then we will discuss the features of the components we have considered for the buoy we will develop: anchors, sensors, data storage, batteries, communication, control unit (CU), camera, and blinking lamp.

2.2 Competitors

Before we thought about “how to develop a buoy”, we did research about our competitors. We focused on relatively small buoys with the same features as the buoy we intend to build. The function of the buoy in regattas will be new, so we put our focus on environmental buoys. We found out that more advanced environmental buoys had following features:

Table 2-1 Competitors [1] [2]

2.3 Anchors

2.3.1 Required information

In order to choose an appropriate anchor it is required to have a prior knowledge on a few aspects. The first and probably most important is the type of bottom that the anchor is going to be placed in. Depending on the type of soil, some anchors will perform better than others. The same anchors when placed in a different bottom will have different performances, sometimes even diametrically different. The second aspect is the load data. In general, there are different anchors for low and high loads. The third aspect is the mooring line configuration. It is important whether it should be catenary or taut leg. Additionally, not always the most expensive or strongest lines are required [3]. An extensive research on this issue is included in Appendix A.

2.3.2 Functions of an anchor

A good anchor must guarantee reliable and consistent performance in relation to three of its functions. First of all, it must be able to gain a hold in the bottom. Secondly, it must be able to provide sufficient holding power to keep a buoy from dragging it. Thirdly, the anchor “should be able to either maintain or regain its hold when the wind or current changes the direction of pull” [4]. If a given anchor does not fulfil these criteria, it is necessary to select another one [4].

2.3.3 Soil evaluation

As mentioned before, the type of bottom has a significant influence on the performance of an anchor. In fact, “the selection of a suitable bottom for anchoring is a much more critical factor than the design of the anchor” [5]. All types of bottoms can be put into four categories [5]:

1. Sand

It is the best type of bottom for anchoring. First of all, it is relatively easy for anchors to penetrate. Secondly, it provides a high holding power. Hard sand is preferable over fine-grained sand. Suggested anchors: pivoting-fluke anchors and non-hinged scoop anchors.

2. Mud

It is a more complex type of bottom than sand. First of all, it has a low shear strength. For this reason any anchor that is designed for this type of bottom needs to have a “broader shank–fluke angle and greater fluke area” [5]. Secondly, mud often constitutes only a thin layer on top of some other type of soil, so anchors that can penetrate through the mud to the underlying material will hold more. Suggested anchors: Fortress anchor.

3. Rock and coral

Most types of anchors do not set in well in these bottoms. Typical anchors with flat, parallel or slightly bent flanks are not of much use here. The anchor must have flanks that protrude from the anchor’s axis to its sides at an angle of even 90 degrees. Additionally, anchors usually cover a great distance and take more time to set into rocks. Suggested anchors: Claw, CQR, Delta.

4. Shale, clay, grassy bottoms

These are the most difficult types of bottoms where the weight of an anchor is more important than its design in terms of its holding power and ability of penetration. Suggested anchors: CQR, Delta

2.3.4 Anchor types and their specification

Based on the collected background information, we narrowed the possible choices to a total of six anchor types, all of which belong to drag embedment anchors. For organizational reasons two separate tables gathering the selected anchors’ main features and their advantages and disadvantages have been organised (Table 2-3 and Table 2-3). Figure 2-1, 2-2, and 2-3 depict the first three considered types: Danforth, CQR, and Delta:

- Danforth anchor

A type of lightweight anchor with flat parallel flukes

Figure 2-1 Danforth anchor [6]

- CQR anchor

Short for coastal quick release anchor. An anchor that is designed to bury itself into the ground by use of its plow shape:

Figure 2-2 CQR anchor [7]

- Delta anchor

A type of anchor with curved, joined flukes:

Figure 2-3 Delta anchor [5]

Table 2-2 Comparison of Danforth, CQR and Delta anchors [4] - [8]

Figure 2-4 to Figure 2-6 depict the other three considered types: Claw, Spade, and Fisherman’s. Their main features are pointed out in Table 2-3 that follows.

- Claw anchor

As its name suggests, the flukes of this type of anchor resemble a claw:

Figure 2-4 Claw anchor [4]

- Spade anchor

An anchor type with flukes resembling a spade:

Figure 2-5 Spade anchor [9]

- Fisherman´s anchor

A traditionally shaped anchor having flukes perpendicular to the stock of the anchor and connected by a shank:

Figure 2-6 Fisherman's anchor [10]

Table 2-3 comparison of Claw, Spade and Fisherman’s anchors [2] - [11]

2.3.5 Conclusions

After assessing the above options, we have decided that it would be best to use the following anchors:

- For sand: Danforth anchor

The Danforth anchor has many advantages. First of all, with its price oscillating between 20 and 40 EUR, it is very cheap, especially when compared to other anchors like the CQR, which costs above 300 EUR. Secondly, it is the lightest of all, which is particularly important as we want the buoy as lightweight as possible. Thirdly, it possesses a good holding power in soft sand and mud where many other anchors may not hold as well.

- For rocky bottom: Claw anchor

First of all, the Claw anchor is relatively cheap. With its price not exceeding 40 EUR, it strikingly beats other types of anchors. Secondly, it resets easily when wind or current changes, and it can make a 360 degree turn without breaking out. Thirdly, its design is particularly meant for rocky bottoms.

2.4 Sensors

2.4.1 Introduction

In order for the electronic buoy to be able to collect any type of data it needs to be equipped with what is called a sensor. The generic definition of a sensor is as follows: “a device that responds to a physical stimulus (…) and transmits a resulting impulse” [12]. As far as the buoy is concerned, the physical stimuli consist of weather conditions such as wind direction and speed, pressure, dew point. In fact, weather buoys can be equipped with a multitude of sensors that respond to many different kinds of stimuli. For example, the station 62029 – K1 buoy owned by the UK Met Office collects the following data: wind direction, wind speed, wave height, average period, atmospheric pressure, pressure tendency, air temperature, water temperature, dew point, and wind chill. [12] [13]

2.4.2 Types of sensors

Examples of sensors for a weather buoy and their construction/principle of operation [14]:

* Buoy orientation sensor.

The wind sensor on a buoy would be of no use if it was not accompanied by an orientation sensor. The reason for this is quite simple - the buoy is not stationary, it rotates, and therefore, does not have a constant orientation. Consequently, any measurements of wind made on a buoy need to be corrected with the measurements of the orientation sensor. It usually “incorporates a hall effect compass sensing the earth’s magnetic field” [11].

- Air temperature sensor.

The air temperature on a buoy is often measured with a platinum resistance thermometer. It is a device that takes advantage from electrical resistance of platinum, a feature which increases approximately linearly with absolute temperature. Therefore, by passing a current through it and measuring the resulting voltage, it is possible to determine the temperature (of course, with the use of an appropriate calibration equation). Moreover, in order to obtain accurate and reliable data, it is necessary to protect the thermometer against solar radiation, rain, and splashes from waves. This is usually achieved by means of a special shield surrounding the thermometer [11] [15] [16].

- Air pressure sensor.

One of the popular air pressure sensors used on buoys is the Vaisala BAROCAP® product. It measures pressure by detecting dimensional changes in its silicon membrane. As the pressure around the sensor rises or falls, the membrane deforms causing a change in the height of the vacuum gap inside the sensor. This in turn changes the sensor’s capacitance, which is measured and converted into a pressure reading. [15] [17]

- Current speed and direction.

An example of a sensor measuring the current speed and direction is the Doppler Current Sensor 3900 (Figure 2 7). It works by transmitting “a short acoustic pulse into the water every second” [11], and then receiving the sound that is reflected by water. Because of the phenomenon known as the doppler effect, this sound has a slightly different frequency from the initial acoustic pulse. By sensing this difference in four directions, and referring it to a hall effect compass, the sensor is able to determine the vector averaged current speed and direction [11] [18].

Figure 2-7 Doppler current sensor 3900 [18]

2.4.3 Wind speed and direction sensor

Wind sensors can be divided into two important types: ultrasonic and mechanical. Ultrasonic wind sensors (Figure 2 8) usually consist of two pairs of transformers that are installed opposite each other in a vertical fashion. When they are set to work, the pair of transformers emit and receive ultrasonic sound waves. The time waves take to travel from one transformer to another allows the wind speed to be calculated. Moreover, “using the combined measurements from several transducer pairs” [19], it is possible to determine the wind direction [19] [20] [21]. Figure 2 8 presents a common ultrasonic wind sensor:

Figure 2-8 Typical ultrasonic wind sensor

Mechanical wind sensors come in many different types, but always consist of the same two components: a sort of propeller and a vane. As far as the wind speed is concerned, a typical mechanical wind sensor has a four blade propeller installed at the end of a longitudinal shaft/housing. When rotated, the propeller produces an AC sine wave voltage signal that is then appropriately interpreted. As for the wind direction, a typical mechanical wind sensor has a flat and thin vane on the other end of the housing. When the wind direction changes, the vane turns and a precision potentiometer senses the change in its angle. The typical mechanical wind sensor is presented in the figure below (Figure 2-9) [22].

Figure 2-9 Typical mechanical wind sensor [22]

The Davis anemometer, as illustrated in Figure 2 10, is a mechanical type of wind sensor. It can measure both wind speed and wind direction. It is strong enough to stand up to hurricane-force winds, yet sensitive enough to detect a small breeze.

Figure 2-10 Davis anemometer

The specifications of the Davis anemometer are listed in Table 2-4:

Table 2-4 Davis anemometer specification

2.4.4 CTD sensor

The CTD sensor, shown in Figure 2 11, is a complex device that serves to measure three important state variables – conductivity, temperature and depth (thus the acronym CTD).

Figure 2-11 CTD

The specifications of the CTD sensor developed at LSA are listed in Table 2-5.

Table 2-5 CTD sensor specifications

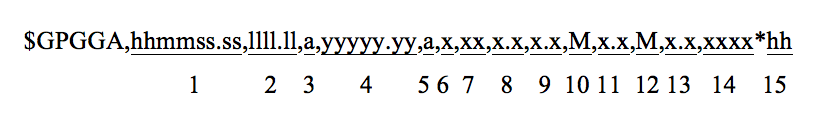

2.4.5 GNSS receiver

GNSS, an acronym for Global Navigation Satellite System, is a satellite system that allows to determine the geographic location of an object anywhere in the world [23]. It operates on the principle of signals being sent from satellites to a receiver on earth. This receiver is a device that receives, processes, and decodes navigation signals and thereby determines its location [24]. One of many such devices is the Superstar II, a piece of hardware as seen in Figure 2-12. Its specifications are listed in Table 2-6:

Figure 2-12 Superstar II

Table 2-6 GNSS receiver specifications [25]

2.4.6 Conclusion

At this point the first prototype of the autonomous environmental buoy will only need four types of sensors: CTD sensor, wind speed and direction sensor, orientation sensor, and a GNSS receiver. All of these devices are readily available at the Autonomous Systems Laboratory. The orientation sensor is an integral part of the microcontroller STM32F3 Discovery, and thus does not need to be added. The wind sensor we are going to use is the Davis anemometer, the CTD – the one developed at LSA, and the GNSS receiver – Superstar II.

2.5 Data Storage

2.5.1 Introduction

When collected, data has to be stored. There are 2 sorts of data storage, primary and secondary data storage. Primary storage typically refers to storage or memory directly connected to and accessed by a computer’s CPU (for instance RAM). Secondary storage, on the other hand, does not directly connect to a CPU and is non-volatile memory. Other differences between the two include the amount of data typically stored on such memory and the speed at which the data is processed [26].

According to The University of Rhode Island [27], the benefits of secondary storage are:

- increase of capacity,

- increase of reliability (they are non-volatile storage devices),

- reduce of cost (secondary storage is cheaper than primary),

- reusability of the secondary storage devices.

In our case the primary data storage will take place inside the microcontroller. Secondary data storage can be done in different ways [28] [29]. These are detailed in the section that follows.

2.5.2 Different types of data storage and their specifications

Secondary storage can be realised in different ways. The most appropriate methods are:

- Hard Disk

A hard disk (Figure 2-13) is a method of data storage that stores and provides relatively quick access to large amounts of data. A hard drive is generally the fastest of the secondary storage devices, and has the largest data storage capacity (up to 4000 GB). Hard drives however, are not very portable and are primarily used internally in a computer system. Another major disadvantage is that it is very susceptible to damage from physical shocks.

- Optical disk

An optical disk (Figure 2-14) is an electronic data storage medium from which data is read and written to by using a low-powered laser beam. It is a flat, circular, plastic or glass disk on which data is stored in the form of light and dark pits. There are three basic methods of storing data on an optical disk: Read-only (e.g. CD and CD-ROM), write once read many (e.g. CD-R) and rewritable (e.g. CD-RW). The three main types of optical disks are:

- CD: a form of data storage that can transfer data up to the speed of 0,2 MB/s. A standard 120 mm CD holds up to 700 MB of data, or about 70 minutes of audio. There are two types of CD: CD-ROM and CD-RW.

- DVD: an optical disk storage media format that can be used for data storage. The DVD supports disks with capacities of 4.7 GB to 17 GB and access rates of 0,6 MB/s to 1,3 MB/s. A standard DVD disk stores up to 4.7 GB of data. There are also two types of DVD's: DVD-ROM and DVD-RW.

- BD: there are 2 types available: Re-Writable and Read Only. Their capacity can vary between 25 and 128 GB.

The main advantages of this storage medium is their low price and the fact that some types do not allow users to overwrite data. Disadvantages are the slow seek time and the fact that data can degrade with time.

- Flash drive

A flash drive (Figure 2-15) is a small external storage device that consists of flash memory. USB flash drives are removable and rewritable. They are a solid-state storage medium that is both inexpensive and durable. Currently, USB 2.0 flash drives on the market are able to reach a data transfer speed of 60 MB/s and USB 3.0 has transmission speeds of up to 640 MB/s. Common used USB Flash drives vary in sizes from 2 GB to 16 GB, but in special cases the capacity can be increased to 512 GB.

The main advantages are the very fast seek time and the fact that it is very portable. On the other hand, flash memory has disadvantages. Like all flash memory devices, the main problem with flash memory drives is that they only can sustain a limited number of write and erase cycles before the drive fails [32]. Anther disadvantage is the limited capacity.

- Flash Memory cards

Flash memory cards (Figure 2-16) are non-volatile computer storage chips. These memory cards currently vary in sizes between 1 GB to16 GB. Flash memory cards have most of the flash drive’s characteristics. They are inexpensive, durable, and are very small. The most used formats are Secure Digital cards (SD card) [34] and micro Secure Digital cards (microSD). There are three formats for regular SD cards , SD (capacity up to 2 GB), SDHC (capacity up to 32 GB), and SDXC (capacity up to 2000 GB). Data transfer speed depends on the speed class the SD-card belongs to, as printed out in Table 2-7:

Table 2-7 Speed classes for SD-cards [35]

In Table 2-8 we made a comparison of the different secondary storage devices:

Table 2-8 Comparison of secondary storage devices

2.5.3 Conclusion

We can conclude that for our application, a small, power efficient, and robust data storage unit is recommended. Therefore we have two options: a flash drive or a flash memory card. Our choice mainly depends on the dimensions and the weight. Due to their dimensions, their lower prices per storage capacity and the fact that they are reconfigurable (if you add more sensors, you can increase the data storage capacity) of flash memory cards, our final choice will be the use of a micro flash memory card (microSD, microSDHC or microSDXC).

An important remark to make is the fact that a flash memory device only has a limited number of write and erase cycles before the drive or card fails. Due to this fact, we will have to replace the flash memory card after some time.

2.6 Battery

2.6.1 Introduction

“A battery is a device consisting of one or more electrochemical cells that convert stored chemical energy into electrical energy” [38]. [39] states that “a battery is an electrochemical cell (or enclosed and protected material) that can be charged electrically to provide a static potential for power or released electrical charge when needed”. We can conclude that a battery is an electrochemical cell that can convert stored chemical energy into electrical energy. There are two main types of batteries, primary batteries and secondary batteries. The difference between them is that secondary batteries can be recharged after all their chemical energy is consumed. In our case, it is recommended that we use rechargeable batteries; otherwise a lot of money will be spent on primary (non-rechargeable) batteries.

2.6.2 Different types of secondary batteries and their specifications

There are different types of secondary battery types: [40] [41]

- Lead-acid

Lead–acid batteries were invented in 1859 by French physicist Gaston Planté. These batteries are one of the oldest rechargeable battery systems. Despite having a very low energy-to-weight ratio and a low energy-to-volume ratio, their ability to supply high surge currents means that the cells maintain a relatively large power-to-weight ratio. They remain the technology of choice for automotive applications (SLI) because they are robust, tolerant to abuse, and because of their low cost. A disadvantage is the presence of lead, a toxic heavy metal.

- Nickel-cadmium (NiCd)

The NiCd battery was invented by Waldemar Junger and patented in 1899. The battery uses nickel oxide hydroxide and metallic cadmium as electrodes. Sealed Ni-Cd cells were at one time widely used in portable power tools, photography equipment, flashlights, emergency lighting, and portable electronic devices. The superior capacity of the Nickel-metal hydride batteries and their lower cost, has largely expanded their market share. Further, the environmental impact of the disposal of cadmium has contributed considerably for the reduction in their use. Within the European Union, they can now only be supplied for replacement purposes; however they can be supplied for certain specified types of new equipment such as medical devices.

Larger ventilated wet cell NiCd batteries are used namely in emergency lighting, standby power, and uninterruptible power supplies.

- Nickel-metal-hydride (NiMH)

A practical replacement for NiCd is the Nickel-metal-hydride battery; it has higher specific energy with fewer toxic metals. NiMH is used in medical instruments, hybrid cars, and industrial applications.

- Lithium-ion (Li‑ion)

The li-ion batteries are mostly used for portable consumer products, such as in laptop computers, moderate to high-end digital cameras, camcorders, and cell phones; it is more expensive than nickel- and lead acid systems and needs protection circuit for safety but it contains no environmental hazards.

- Li-polymer (Li-Po)

Lithium-polymer (Figure 2-17) differs from other battery systems in the type of electrolyte used. To make the modern Li-polymer battery conductive at room temperature, gelled electrolyte is added. All Li-ion polymer cells today incorporate a micro porous separator with moisture. The correct term is “Lithium-ion polymer” (Li-ion polymer or Li-polymer for short). Li-polymer offers slightly higher specific energy and can be made thinner than conventional Li-ion, but the manufacturing cost increases by 10 to 30%. Despite the cost disadvantage, the market share of Li-polymer is growing. Li-polymer cells also come in a flexible foil-type case; while a standard Li-ion needs a rigid case to press the electrodes together, Li-polymer uses laminated sheets that do not need compression. A foil-type enclosure reduces the weight by more than 20% over the classic hard shell. [42]

Figure 2-17 Lithium-polymer battery [43]

The table below (Table 2-9) sums up the characteristics of the different secondary batteries:

2.6.3 Conclusion

We can conclude that a lithium-polymer battery has the best performance properties. Especially the high specific energy density and the high nominal cell voltage are big advantages. Lithium-polymer batteries are the best option when you have to take weight into account. The only disadvantage is the price. Nevertheless, as LSA already has lithium-polymer batteries available, our first choice goes to Li-polymer batteries, to build the electrical circuit for the first prototype. An important remark is the fact that Li-polymer batteries cannot be mass produced in 6V packs because their nominal cell voltage is 3,6V. Therefore our second choice will be the usage of NiMH batteries due to their high specific energy density and their low toxicity.

2.7 Communication

2.7.1 Introduction

In our project we need a communication device for two purposes:

- To exchange data with the user on demand (send data from sensor / receive updates of program code),

- to communicate automatically with autonomous sailing boats (send data from sensors).

According to this, we need bidirectional communication. We also want it to be an inexpensive open-source solution (to make the buoy as cheap as possible). For sustainability and autonomy reasons, it should be power efficient, which probably will imply limitations on the range of communication.

2.7.2 Related projects and products

We were searching for products, similar to ours, which also need to communicate wireless. We found two exemplary solutions in already existing buoys:

- Coastal Monitoring Buoy CMB 4280 - it can use one (or more) of these communication techniques [11]:

- Radio Modem, Frequency of 370 to 470MHz,

- GSM Modem,

- VHF Radio Transmitter,

- UHF Radio Transmitter,

- Argos Transmitter.

- “A Low-Cost Sensor Buoy System for Monitoring Shallow Marine Environments” [45] uses the following:

- RF module with frequency range of 2394 to 2507 MHz [46].

As the buoy is intended to cooperate with autonomous sailing boats we have also checked what kind of communication they use, and came out with these examples:

- Wi-Fi [47],

- GSM [48],

- HF radio modem with frequency of 869.525MHz [49],

- Bluetooth module [48].

Generally, the technology used depends on the purpose of the device and the intentions the developers give relevance to.

2.7.3 Communication technologies and their specifications

There are many wireless communication technologies which differ in speed, range, effectiveness, and in several other characteristics. Below there is a short description of often used standards nowadays.

- GSM is “the world’s most widely used cell phone technology” [50]. It is the second generation standard for mobile networks. The distinctive characteristic of GSM is the use of SIM cards as unique identifiers inserted into devices. GSM can use two main techniques of data transmission: GPRS and EDGE. GPRS allows data transfer at speed of 30 to 50 kb/s. EDGE, the newest solution, gives theoretical data transmission speed up to 296 kb/s.

- UMTS is “a third-generation (3G) broadband, packet-based transmission of text, digitized voice, video, and multimedia at data rates up to 2 Mb/s” [51]. It is based on GSM standard, and it is an improved technology for mobile devices. It also allows its users to connect to the internet. It is mostly used in mobile networks all over the world.

- Wi-Fi - broadly known group of standards for wireless networks (especially computer networks). Nowadays it is becoming probably one of the most popular WLAN creating technique in the world. Depending on particular standard (defined by IEEE) it uses different radio frequencies and provides its users with different data transmission speeds (up to even 1Gb/s). In local applications it is common that devices need to connect to access points (special devices functioning like a hub), in order to get access to a network. There is also a second mode of Wi-Fi: Ad-hoc, which allows devices to connect with each other directly [52].

- Bluetooth - well-known wireless communications standard especially for short-distance connections. Often used to provide wireless communication between simple devices to replace traditional wirings. Connection is made directly between devices with average speed of 1Mb/s data transfer. The Bluetooth uses open-source standard regulated by IEEE organization [53] [54] [55].

All described communication standards are compared in Table 2-10 below, using their crucial characteristics:

Table 2-10 Comparison of communication units

Besides the communication modules compared in Table 2-10, sometimes an additional antenna is needed to extend the power of signal (the price of an antenna is around 10 EUR):

2.7.4 Conclusion

As it can be concluded from Table 2-10, the compared technologies in some characteristics differ a lot, in some are very similar. GSM and UMTS can be eliminated, considering this project, because of their high power consumption, expensiveness, and low data transfer. What is more, these types of communication are dedicated for long-distance applications. Wi-Fi and Bluetooth are more suitable for our purpose. Finally, we choose Wi-Fi as the best solution. Wi-Fi cards are very cheap, have wider signal range and larger data capacity than Bluetooth. What is more, the autonomous sailing boat FASt (described in [47] ) from FEUP (one of University of Porto's faculties) is compatible with IEEE Wi-Fi standards so that further tests of buoy-boat communication can be easily done.

2.8 Control Unit

2.8.1 Introduction

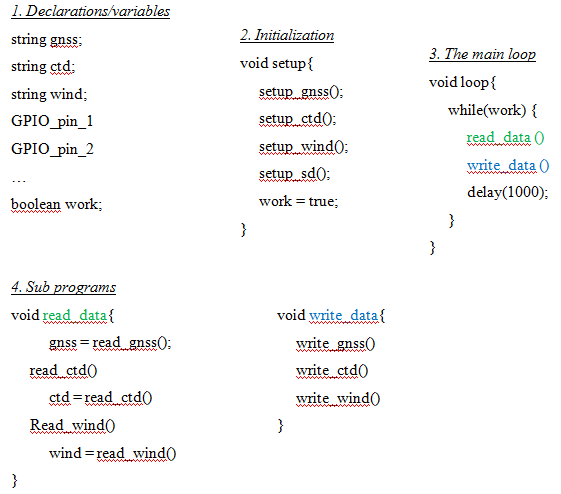

In the project we need to have multifunctional a control device to manage functions such as receiving data from sensors, saving data marked with GNSS time stamp on data storage and controlling communication with user. According to that, the obvious solution is to use an integrated microcontroller board (Figure 2 18) that can easily be customized. This is the reason why specific microcontroller boards are compared in this State of the Art section.

A microcontroller is “a compact microcomputer designed to govern the operation of embedded systems in motor vehicles, robots, office machines etc. (…). A typical microcontroller includes a processor, memory, and peripherals“ [56]. It is an extremely small device what makes it applicable almost everywhere. Very often, microcontrollers are sold not as a single devices, but already attached to PCBs with numbers of peripherals, additional pins, and small circuits to make it easy to use in various purposes.

2.8.2 Different microcontrollers and their specification

Table 2-11 presents five different products we have selected, (including three suggested by LSA) to compare their characteristics:

- STM32VL Discovery,

- STM32F3 Discovery,

- STM32F4 Discovery,

- Raspberry Pi model B,

- Arduino Uno.

2.8.3 Conclusion

Our choice is the STM32F3 Discovery kit. It has a powerful microcontroller with numerous serial interfaces (e.g. USART, SPI), and many GPIOs. Even though the F4 series one is more powerful, contains Ethernet interface and has the possibility of easily attaching external memory such us SD card (SDIO interface), it does not have an E-compass included. The E-compass is an essential sensor to calibrate the wind direction. Having it already in the control unit, a purchase of an external one is not needed. What is more, the high computing power of F4 is not necessary in the buoy we develop.

Why have we chosen one of STM32 Discovery kits? LSA, our client, suggested it – they already have them, so there is no need to spend money for the purchase. Moreover, they have experience with these microcontrollers, so we can get support from LSA. It is relevant to mention that we have no experience in the microcontrollers area, so this was an important criterion.

2.9 Camera

2.9.1 Introduction

Adding a camera would implement a financial benefit, because we could record, and sell the moment when the boats pass the buoy There are different kinds of cameras available on the market. Offers range from basic cameras to cameras with a lot of special features. It is obvious that prices will increase with extra functions and benefits.

In our case we have to keep in mind that there are important placement conditions:

- Corrosion resistance,

- UV-radiation,

- saltwater-surrounding.

In terms of developing the prototype as cheap, but sustainable, as possible, different options appeared. We thought about three options:

- Buying a waterproof camera,

- buying a basic camera and a waterproof case/hull,

- buying a basic camera and build a self-made waterproof case/hull.

2.9.2 Camera types and their specifications

In Table 2-12 you can find the main features of the different camera types:

2.9.3 Conclusion

We have 2 options for the addition of a camera depending on the amount of money the client want to spend. The first one is to buy an expensive waterproof camera. In this case we would suggest a 360° waterproof camera (e.g. Superyacht Underwater Colour Surveillance System) as shown in Figure 2-19. The second option is to buy a cheap camera (Logitech HD Webcam C270) and place it in a water- and UV-proof hull, as shown in Figure 2-20.

Figure 2-19 Proposal 1: Superyacht Underwater Colour Surveillance System

2.10 Blinking lamp

A blinking lamp on top of the steel structure will ensure that the buoy is visible for ships. When we visited the shop “dismotor” in Matosinhos to inform about the anchor, the salesman advised us that Figure 2-21 would be the best option for a buoy placed in a river to ensure moderate visibility.

Figure 2-21 S12 blinking lamp [62]

This blinking lamp is standard provided with a lamp of 12V/10W with a luminous flux of 100 lumen. Because we want to reduce the power consumption, our final choice will include a 12V LED, called “BA15S”. The luminous flux of the LED is 90 lumen with a power consumption of 3W. For a similar luminous flux, we reduce the power consumption with a factor 3.

3. Marketing Plan

Primary Remark:

Within the context of merchandising the product after finishing the prototype, the current status is still that a range of important and marketing-essential decisions have not been made. Even though the circumstances for running an appropriate analysis are not totally given at the moment, we worked out as much as possible.

3.1 Introduction

In times of worldwide rising online sales, it is an absolutely essential step to analyse the world market. Our future customers are able and willing to search international markets, taken from international acting companies. Therefore, in addition to studying customers´ needs, it is indispensable to analyse competitors, as well as their strengths and weaknesses on a global market.

Our product, the buoy, will probably fit in different markets with varying needs. Being equipped to implement two different functions, the buoy can be seen as an ´environmental measuring unit´ for all kind of researching purposes on the one hand, and on the other hand as a ´regatta buoy/beacon´ especially developed for autonomous sailing regattas. During planning/development it will be a priority to make the buoy adaptable. For the stated reasons we will have different markets to analyse, and approximately also to aim at.

The planned first function, the measuring feature of the buoy already exists. The main field of application is to monitor environmental data for scientific statements and analysis (e.g. buoys function as a tsunami early warning system in the Indian Ocean). Most of the existing buoys are individually produced unique items, which serve the specific needs of the project/mission/customer. Governmental/private weather stations or services, companies as well as the maritime sector in total depend on environmental data (either provided by a third party or measured by themselves). Focusing on an industrial use of our buoy or the measured data as a product, and also on private institutions, it might be possible to penetrate a niche (B-to-B).

At the same time the second planned function offers expandable future prospects. To develop a regatta buoy, especially for autonomous sailing regattas, could implement new unknown needs in this relatively young industry/market. We also provide new additional features like the camera.

3.2 Market Analysis

3.2.1 Macro Environment

According to a report of the German “GESELLSCHAFT für MARITIME TECHNIK e.V.” (Association of Maritime Engineering), in 2001, the marine technology sector had already reached a total volume of 150bn EUR sales per year in 2000 and will increase at least the next twenty to thirty years [63]. Present statistics confirm this development. The future outlook in this sector will mainly be influenced by eco-political and economic trends, such as: usage of renewable energy, sustainable usage of maritime resources or monitoring of climate- and environmental changes. The report also highlights the structure of the German marine technology sector. The dominant companies on the market are small and medium-sized businesses. This can be reflected to the world market, where similarly structures exist.

In addition referring to the “WORLD OCEAN COUNCIL” the so-called “Growing Multi-Use Ocean” is taking place. Offshore renewables like wind farms, shipping, mining/dredging, aquacultures or submarine cables, to list just a few, are expanding markets which list a global solid monetary increase [64]. Especially the offshore wind turbine market provides a significant increase. An annual investment of 3.4bn EUR to 4.6bn EUR is listed in 2012 and numbers are supposed to go up [65]. Due to presumable further development and new technologies for utilising the renewables, it could be an interesting option. Particularly for wind turbines, stored data of wind power/current/waves etc. (long time measurements) are an important factor for analysing locations to place a wind farm or a wind turbine [66]. These are things we are able to provide. In line with this information it appears that the macroeconomic environment in context of the maritime technology sector (in our case: measurements) is affected by economical, technological, natural, political, and cultural factors:

- Economic environment:

As illustrated above, the international business development in our sector is expanding. Although the world economic crisis, especially the European crises, is still a big issue, investors/enterprises are still keen to invest with profitable success. Focusing particularly on Europe and Portugal, looking at proceedings during this ongoing crisis, it becomes clear that the wind energy sector is still at its starting point. Even barriers are insurmountable at the moment; it might be an interesting future market. Not only was the first offshore turbine inaugurated in summer 2012 on an innovative floating foundation called “WindFloat” in Portugal but also new factories have been built recently [67] [68].

- Technological environment:

In general, these days the pace of innovation is constantly accelerating. Innovations in using renewable energies are expected. New technologies in context of implemented components for our buoy could have an impact on the effectiveness, as well as on the price. These aspects could make it possible to develop new markets, and for instance, to make the buoy more affordable also for private usage.

- Natural environment:

From the nature´s point of view, it is and will always be important to measure relevant data and to evaluate it. Nowadays the restriction of pollution is still of prime importance. Therefore, it is unavoidable to register environmental and climatic changes as soon as possible, to ensure a quick political/economical reaction.

- Cultural/Social environment:

The general public, society at large, experiences a raising ecological awareness. Hamper the climate change by recycling material, driving a fuel saving automotive and/or saving up raw materials, leads to a new importance. It is an international concern to harm pollution, pay attention to our planet, and save energy. As a result an intensified urge for environmental knowledge is appearing. E.g. more and more privately run weather stations get installed. Private measured data is available from different sources worldwide. Due to the Internet, private meteorologists have become interested in measuring data, analysing it, and making it available online.

- Political environment:

In most parts of the world, but especially in Europe, the political parameters are given to adopt a technology like the one we propose to develop. Politics fund maritime measuring technology (e.g. in Germany), and also support entrepreneurial start-ups [69]. Besides inner-European trading will be supported by trade agreements.

Even if the economical/technological environment supports further research and development, the on-going European crisis could harm a further proceeding from a political point of view. Especially in Portugal, expenses are being cut at the moment and projects like ours could be harmed by a lack of budget. The finance ministry of Portugal has blocked the majority of educational benefits and expenses for research purposes until the end of 2013. The researching sectors of almost all universities suffer and will keep on suffering from these savings. 41 Highlighting the legislation of mooring and placing buoys, it became apparent that placing a buoy needs to be confirmed by the responsible department, but it is in general possible for scientific as well as private purposes [70].

3.2.2 Micro Environment

- Internal:

In association with being an upcoming start-up, consisting of four advanced students in Portugal with no experience in marketing this kind of product, we will analyse global competitors but primarily choose a specific target market for earning know-how and market share. We don ́t have any previous information or management structures we can build on. Every strategy, every single step has to be created and implemented by dealing with a limited budget. The fact that all team members have gained their knowledge at different faculties in Poland, Belgium, and Germany can be helpful and supportive. Also the single motivation of all members to implement a successful, profit-gaining product is a plus.

- Suppliers:

Concerning the value chain management, international trading, and procurement is becoming easier. Political trade barriers are minimised and make it possible to largely ensure the availability of all required resources and components. In addition, most of the components are mass-produced articles, which are obtainable worldwide. Already chosen regional suppliers like “ALTO–Perfis Pultrudios, Lda”, will provide us with more specific components like the hull. As a result, the procurement of materials and components will not be a problem and suppliers can be chosen by quality, prices, reliability, and matching company philosophy. As it is helpful, an option could be to use existing supplier networks to compare and select them. The introduction of online networks shortens the ́time-to-market ́ and makes it possible to focus on more important matters like the development, production or marketing of the product.

- Intermediaries:

Although it will be hard to realise intermediaries at the moment, future approaches could contain this marketing option. In addition to direct B-to-B marketing, it could be helpful to find and activate partners/intermediaries who could add the product to their assortment (e.g. Sailing-outfitter, electronics stores, etc.).

- Customers:

Referring to the two different main functional fields of application, several different target markets/customers are needed to consider. On the one hand businesses/governmental institutions/research establishments/private individuals (1) that have an interest in measuring environmental data in a maritime surrounding, on the other hand research institutions/regatta attendants/sailing clubs and federations, who could be interested in receiving the measured data for sailing purposes (2).

(1)

In order to analyse the market, we contacted geographic faculties in Europe which have already developed buoys to get more information about buoy developing, coast protection, collected data usage, and customers´ needs. According to Dr. Vanselow´s (R+D Centre West coast, University Kiel) professional point of view, especially offshore-energy companies have really specific needs that require development experience in context of offshore conditions. Referring to his experience in developing measuring buoys for business usages, it is almost impossible to compete with commercial suppliers. International wind energy companies´ won´t choose our product at the moment if they have other options. A market penetration in this B-to-B area is really difficult [71]. In order to find more customers in other markets, one option might be to include governmental and promoted areas. Governmental institutions, research centres (biologists, meteorologists or oceanographers) might have an interest in measuring data in a watery environment. Also private individuals could have an interest in our product, doing private research. Plenty of measuring data is provided online, published by private people with their own weather station. E.g. some websites online contain information measured by buoys located in lakes [72].Cities or councils could be an option as well. Areas, cities that have a big interest in tourism (e.g. Porto or even smaller ones), and have a connection to waters could place the buoys near the coast in front of the skyline, the river or a lake and publish the measured information online. The optional attached camera would make it even more interesting for tourism purposes. All in all it appears that different markets are interesting for the further planning. Business markets, governmental markets as well as consumer markets are an option.

(2)

Another target market, which is also the primary reason for developing the buoy, is the autonomous sailing “sport”. Currently no compatible measuring buoy exists. The competitions are annual happening regattas that proceed under different conditions and following various aims (Atlantic crossing, offshore etc.). “In many fields of robotics, competitions with memorable goals cause the attention of media and the interested public, and therefore give a strong incentive to research and development in the particular area” [73].

As shown in Table 3-1, the first competitions were established in 2006. Since the beginning other competitions have been founded and the events became more famous. The attendants are primarily university departments from different countries, which are supported by government aid as well as the competition itself.

Table 3-1 Summary of different regattas

Analysing Figure 3-1 leads to the result that the numbers of participating boats are still increasing and an upward trend exists.

Figure 3-1 Number of boats competing in Mircotransat, SailBoat, and WRSC [73]

One of the main goals of the Microtransat is to achieve the Atlantic-crossing. As seen in Figure 3- 1, in 2010 just one boat attempted and it failed. The on-going trend in developing and achieving the goals combined with the statement above highlights the trend of the “market”. To cross the Atlantic a lot of measurements and further developments need to be made. For this reason the university departments as well as other institutions interested in a successful crossing (e.g. shipping companies) have a need to earn as much information as possible. Our buoy could provide the needed information and also deliver additional benefits like the camera function.

Thinking about the question “Who needs measured data in context of a maritime environment?”, human sailors have been considered as well. Sailing as an Olympic event is a popular sport that is dependent on wind and the circumstances on the water. Professional sailors have an unavoidable need for weather information and analysing its possibilities, if they want to sail appropriately. Currently, no specialised buoys for sailing purposes exist. Information is provided online by third party services or locally at the spot. For a market research purpose, we surveyed some members of the “Sailing Team Germany” to get more information about their specific needs during training sessions and competitions. Sixty-one professional sailors of the “Sailing Team Germany” (http://www.sailing-team-germany.de/) answered the survey. Evaluating the survey below (Figure 3-2 to Figure 3-6) it seems that sailors have their specific unsatisfied demands. For sailors it would be helpful to “scan” the whole training area, for example a real-time connection between the buoys and the supporting motorboat (coaches) would be a great benefit (Figure 3-5). In general, the professional sailing sport could be a target market as well. Countries compete which each other to win competitions. In case of selecting this kind of market, focusing on coastal countries with huge sailing history and present participation at international sailing regattas could be an option. To mention a few: Germany, Portugal, GB and France.

Figure 3-2 Survey Question 1

Figure 3-3 Survey Question 2

Figure 3-4 Survey Question 3

Figure 3-5 Survey Question 4

Figure 3-6 Survey Question 5

Note: The technique would not be allowed in competitions according to international regulations and survey results (Figure 3-3).

- Competitors:

In an international environment the majority of buoy-producing companies serve different markets. As summarised in Table 3 2 the majority is producing inflatable signal- /mooring buoys or unique measuring buoys for R&D and business purposes. Also some suppliers provide commercial measuring buoys in different categories and for various needs. During the competitor analysis it has been approved that the market mainly consists of small and medium-sized businesses that score with long-time experience. Other competitors could be educational institutes and university faculties. During our research we found several different departments (mostly in Germany) that develop or have developed unique buoys with the same functions.

Table 3-2 Competitors that produce measuring buoys for business and scientific purpose

In addition, we did a research for specific suppliers to check what the benefits of other buoy components/systems are. Thinking about other purposes for our technique/electronic, it might be a possibility to just sell the technology of the measuring unit instead of selling the whole buoy. It became apparent that most suppliers already acquired a lot of experience in the maritime measurement businesses, and captured market shares. To compete with them we need to find solutions/strategies that gain market shares rapidly. Table 3-3 lists a couple of German competitors that offer maritime measurement modules similar to the functions we offer.

Table 3-3 Developers/Suppliers of measuring buoys/components

At the bottom line it becomes clear that established competitors score with experience, already existing market shares, client base, and over years gained know-how in a professional environment. Trying to compete with their strengths will be challenging at the beginning. From our point of view internal weaknesses could be advantages. Being a start-up with no structure means simultaneously that we are much more flexible in comparison with our competitors. Penetrating new markets, or putting it another way, creating other markets based upon our flexibility could be one possibility to get customers and work profitable. Contacts for instance to the Sailing Team Germany offer huge possibilities in order to create markets.

3.3 SWOT Analysis

To formulate strategies and clear objectives, an essential step is to analyse the business from a resource based view as well as its external environment. Including the results of the previous market analysis it is possible to outline specific Strengths, Weaknesses, Opportunities and Threats (SWOT) for our company, product, and intentions.

Table 3-5 SWOT – breakdown

3.4 Strategic Objectives

In the interest of outlining a well-performing marketing plan, it is necessary to define strategic objectives in a limited duration (usually three to five years) to aim at. As a result of setting concrete aims, it will be possible to control and approve the on-going planned progress of our business in the future.

Figure 3-7 Market entrance as a function of time

Further objectives:

- Gain as much experience/know-how in the first years as possible

- Improve products, structures, systems etc.

- Reach Break-Even-Point after three years

- Sale of five buoys in 2014

- Sale of forty buoys in 2017

- Penetrate markets in order of time

- Geographic expansion

- Customer satisfaction

- Establish company, its policy and name by 2017

- Expand product line (Professional Sailing)

3.5 Segmentation

As a result of the analysis regarding the product, company, and surrounding, a SWOT-breakdown (Table 3-4) highlights the main aspects. Strengths and weaknesses shown from the resource-based-view as well as opportunities and threats from the market-based-view give an outline of the current situation. Concluding the above analysis´, it stands out that some markets are more interesting for our start-up than others. At the beginning of the analysis the focus was set on the increasing wind-energy-sector that seemed to offer great opportunities. Referring to the statement of Dr.Vanselow again, it will be almost impossible for a start-up to win market-shares without know-how and the necessary budget [71]. Combining this statement with results out of the analysis, the priorities need to be changed. Measure environmental data to find wind farm location in Europe or elsewhere is a really important but difficult issue. Energy businesses will probably not work with an inexperienced start-up. At least for the moment it is too risky. The high number of adept competitors and a lack of R&D resources create market barriers, which are difficult to overcome. In future plans, precisely in times like these, where scarcity of raw materials and ecological awareness are global, huge issues, it could be interesting to include these markets and support finding the right location for them (e.g. wind farms). In our case the attractiveness of markets depends on the difficulty of the market entrance. According to the SWOT-analysis (Table 3-4), the market segment has to meet the requirements of an easy access with small or non-existing market barriers. The circumstances of our start-up as well as our product will lead to the tasks of locating and penetrating new or at least young markets as well as to create new needs in different segments. Regarding this conclusion, it is possible to choose from several of the analysed markets and set objectives (Figure 3-7). In order of priority the most attractive markets are differenced by the two main functions:

- Regatta Function

- Autonomous sailing (1)

- Professional sailing (2)

- Measuring Unit Function

- Touristic cities/councils with adjacent waters (3)

- Private institutes/associations, hobby-meteorologists (4)

- ——————————————

- Scientist/research institutes/governmental authorities

- Renewable energy businesses.

In terms of being a start-up the basic idea of developing the buoy leads to four target markets/segments for the planning period. As shown in the analysis, the prime objectives of autonomous sailing boats are not reached. The increasing numbers of participating boats and in addition, the regattas show the interest in research. Future perspectives might contain extra budgets for developing purpose if, e.g., shipping companies could benefit. Furthermore there are no competitors at the moment. The innovative function and compatibility with established boat protocols might create needs, from which the customers (in this case universities and research facilities) could benefit. For these purposes detailed information needs to be provided (Data sheets, user manuals, etc.). In general, the advantages of different functions for sailing and measuring could also develop benefits for other purposes. Due to the modular system, the certainly manageable size and weight, the ability of reconfiguration and the addable gadgets like a camera, we could also aim at other markets. For scientists, tourism, and water sport our buoy with its equipped features could be enrichment. In the present there are not many commercial competitors for private or business purposes in Europe. One producer of buoys for measuring data, BLUESKY Wetteranalysen (Table 3-3 Developers/Suppliers of measuring buoys/componentsTable 3-2), placed their products primarily in the Austrian and Swiss markets. They offer measuring buoys for lakes and rivers, which provide direct information about the current situation at both, lakes and rivers. Their customers are mostly cities/townships which use the data for tourism and watersports, for instance. To segment this market geographically, highlighting tourism, Portugal in particular is famous for being loved by tourists. In 2010, almost seven million international tourists visit Portugal [74]. Pressing forward in these markets and offer the buoy to cities/townships could gain a lot of customers. Channels of distribution would be short and we would be seen as a regional supplier. In case of choosing Porto as an example for placing the buoy in the Douro River, benefits like providing live weather data on a touristic homepage as well as having camera broadcast footage, could be generated. In addition the city of Porto would support local students and companies which supports an image improving. Similar benefits could be generated for non-corporate purposes. The modular system provides optional sensors to choose from. Private persons/meteorologists could customise their specific buoy and profit by flexible features and approximately proportionate affordability. In terms of our objectives it also appears that professional sailing sport is an interesting segment to aim at. The survey outcome as well as personal conversations between our start-up and the Sailing Team Germany resulted in the interest and need of a customised measuring system for training purposes. In order to accomplish the objectives to serve this prospective segment, it is unavoidable to earn as much experience as possible during the first years and develop a customised product before 2018 that supplies the individual requirements of this customer.

In total all segments are based on the same characteristics. Target-segments are geographical or for occupational reasons close to waters/coasts and have a need of measured and provided maritime data. The general customers we aim at have information-requirements either for themselves or for providing it to third parties. Involving also the fact that we are a group of four advanced students in Portugal, who don´t have any experience in marketing or developing our product, we will firstly concentrate on the inner European market for earning know-how and experience. Highlighting the Portuguese and German market, in especially penetrating the regatta market as well as tourism market, offers small barriers easy to bypass. At first implementing our product in the market of autonomous regattas means we could adopt a pioneer role and adjust our product as well as our marketing to this specific market within its needs. Simultaneously, an improved understanding of segments and customers would be gained by presenting the product to touristic cities just as private meteorologists/scientist. The amount of obtained experience will be an influencing factor for the companies´ further proceedings in other markets (e.g. professional sailing or renewable energy businesses).

3.6 Strategy/positioning

We want to act and be seen as a sustainable, motivated young company that cares about the environment and the people´s needs. Therefore, we will be oriented towards the customers from the start. We are interested in innovations and in developing new ways of living, working, etc. supported by sustainable customer relationship management. For long-term planning, based on the market segmentation and SWOT – breakdown (Table 3-4) we try to work also product-oriented. High quality, reliability and on-going development in correspondence with gaining know-how and experience are our internal main objectives. Successful positioning of our product on the chosen target markets, like regattas or cities/townships assumes a concrete strategy that is supporting our objectives. Regarding to the already done analysis and its results, following the flanking strategy is probably the most appropriate marketing approach we could use. Instead of attack already existing leaders/products directly, we are going to penetrate segments where competitors have not established either strong positions or have not even placed products or earned market shares. For circumventing market barriers as well as similar products, it is necessary to serve a differentiated product that satisfies unknown, new-created needs. In our case the buoy is a differentiated object, targeted to young, less penetrated segments like the regatta boats, tourism as well as professional sailing that are segmented by geographical or occupational reasons.